Products

Structure and features of butterfly valves

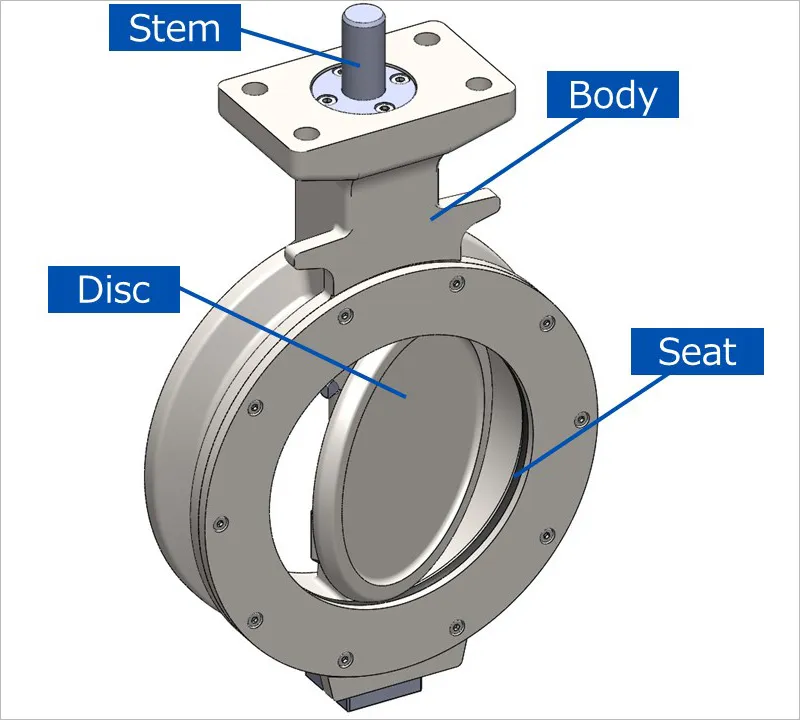

Basic structure and mechanism of butterfly valves

A butterfly valve controls fluid by rotating a disc in a short cylindrical body.

Center disc type (C500 type) and double eccentric type (KM200 type and C200R type) are available.

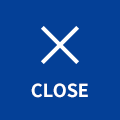

①Center disc type (C500 type)

Center disc type

The center line of the stem passes through the centers of the disc and the sealing surface.

Taking advantage of its simple structure, we manufacture PFA lined butterfly valves with excellent corrosion resistance.

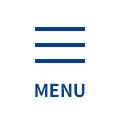

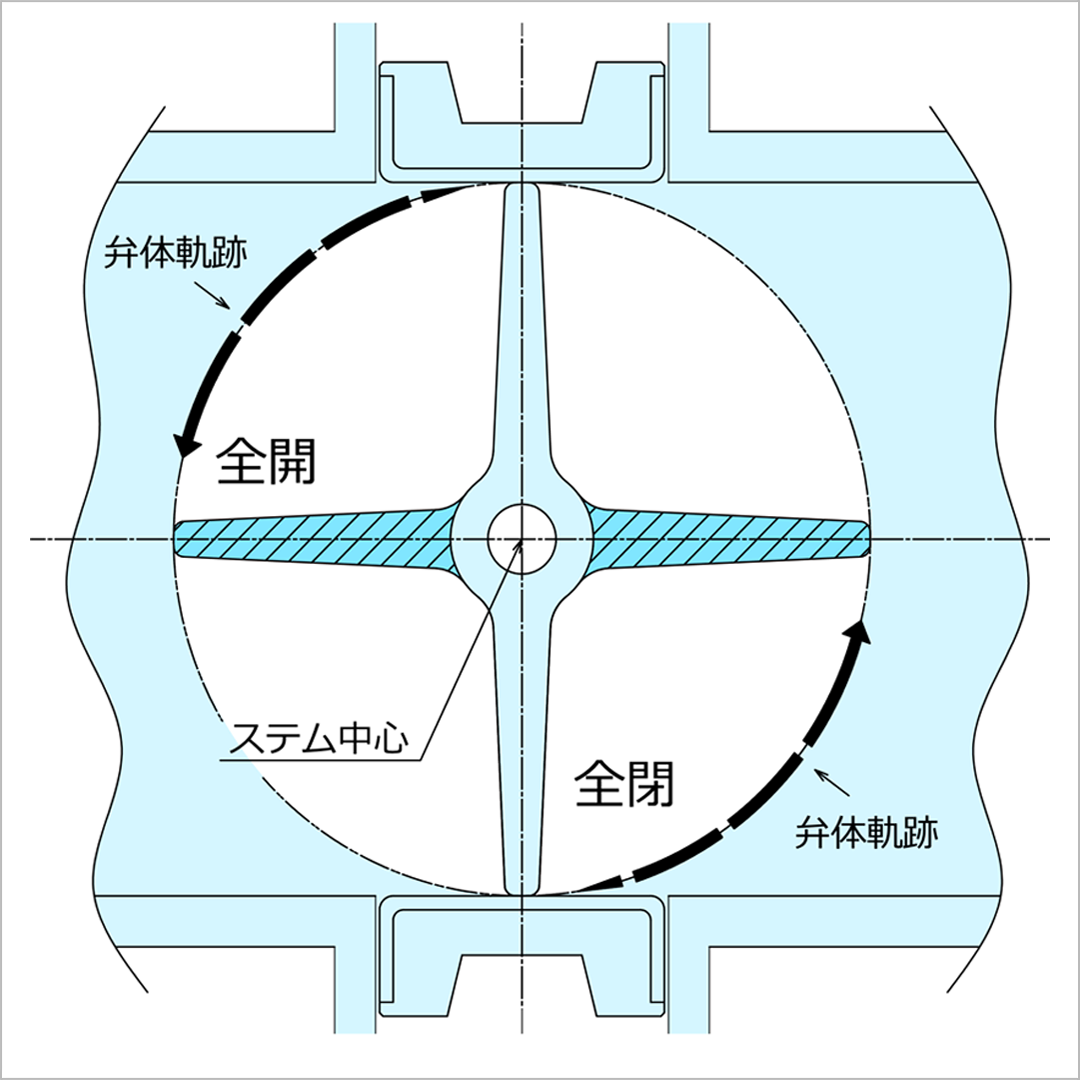

②Double eccentric (KM200 type, C200R type)

Double eccentric type

The center line of the stem of the disc is offset from the center of the seat ring and also offset from the centerline of the piping.

Therefore, when the valve is opened or closed, the disc separates from the seat ring at a slight rotation angle due to the cam action caused by eccentricity, thus reducing wear on the sealing surfaces.

The double eccentric type is superior in valve seat seal ability, and in addition more choice of the materials such as rubber and resin seats, metal seats are available.

Our high-performance butterfly valves made of stainless steel or cast iron use this structure.

Features of butterfly valve

①Excellent operability

Excellent operability and visibility due that the valve can be fully opened and closed easily with 90-degree rotation.

②Space-saving and compact design

Light weight and short face-to-face dimension compared with other type of valves. It can be manufactured from small bore to large bore.

Compared size and light weight with shorter face-to-face and is lightweight and compact.

③Superior in flow control

Flow characteristics close to equal percentages and 20 to 30 : 1 rangeability make its excellent flow control available.

④Actuators are selectable by the operating conditions

By mounting actuator and connectors, it is easy to automatize.

Lever, gear, pneumatic and electric operated are applicable.

⑤Compatible with a wide range of fluid conditions

A lineup of reinforced PTFE seats, rubber seats, and metal seats is available for a wide range of applications. Butterfly valves for pharmaceutical plants are also available.

Related Information

Download

Inquiries about this information

For the production specifications, please click here

(Please feel free to contact us if you have any questions or

any other products which are not described here.)